CAN I USE CUTEK® OVER PRE-OILED TIMBER?

IN MOST CASES, THE ANSWER IS YES!

If your timber has been pre-oiled with CUTEK® oils… then you can definitely use CUTEK® oils over the top. In fact, we recommend applying a coat of CUTEK® Extreme CD50 or CUTEK® Wood Preservative after your timber has been installed to increase the dimensional stability.

If your timber has been pre-oiled with a different oil coating… then you need to do a simple test to see if CUTEK® can properly penetrate into your timber. CUTEK® needs a wood surface, free of any barrier that stops CUTEK® moving deeply into your wood, allowing it to work properly.

NOT SURE IF YOUR WOOD HAS A BARRIER ON THE SURFACE?

Simply pour a few drops of water onto your pre-oiled timber and watch to see if it sinks right in and penetrates. If the water can get in, so can CUTEK®! You are free to apply CUTEK® as desired.

(Note: try this test on a few areas of your timber, especially areas that have not been exposed to the sun or the elements – pre-oiled wood that is exposed to UV and rain generally has less of a barrier to penetration than wood that is sheltered from the weather).

If the water that has been applied beads up, then there is a barrier preventing liquids from getting into the timber. To remove this barrier, simply apply CUTEK® Quickclean to the timber at a dilution of 1:1. (1 part water to one part Quickclean). Gently agitate the timber surface with a broom or deck scrubbing brush and rinse thoroughly. Allow the timber to dry. Retest with a few drops of water to ensure the barrier has been removed successfully. When you are satisfied that any barrier has been removed, you will be free to apply CUTEK® as desired.

Remember, regardless if there is a barrier to penetration or not, for best results, it is always best to Prepare your wood properly, before you Protect it. CUTEK® Quickclean with a dilution of 1:1 is the ideal Prepare product to prepare your pre-oiled wood prior to receiving CUTEK®.

STILL NOT SURE…

Remember CUTEK® provides free samples. We always recommend that you test a small patch prior to proceeding with your whole project to determine if CUTEK® is able to be used successfully.

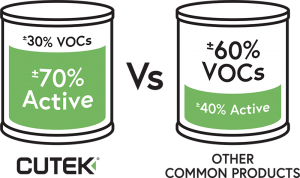

THIS SEEMS LIKE A LOT OF EFFORT – WHY SHOULD I BOTHER USING CUTEK® INSTEAD OF ANOTHER AFTER MARKET WOOD OIL?

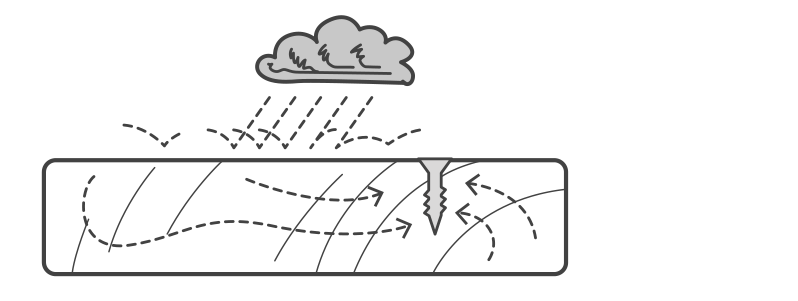

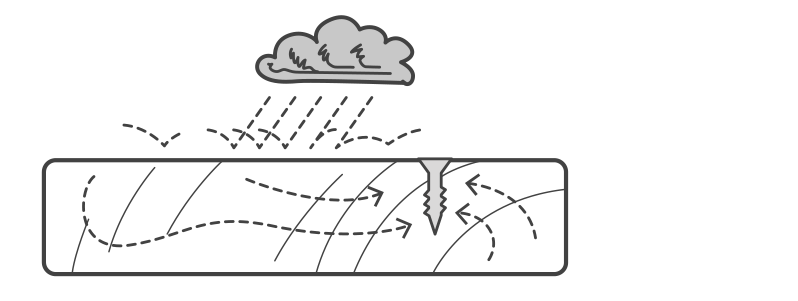

CUTEK® does something that other oils usually don’t do. CUTEK® penetrates deeply inside your timber and then remains permanently mobile with a self-healing effect long after the CUTEK® coated surface has dried. What this means is: even if you cut your timber, or pierce it with a nail/screw, the oil inside will move to that spot, essentially preventing water from being able to get in.

Where CUTEK® is, water can’t be.

WHY DOES KEEPING WATER OUT MATTER?

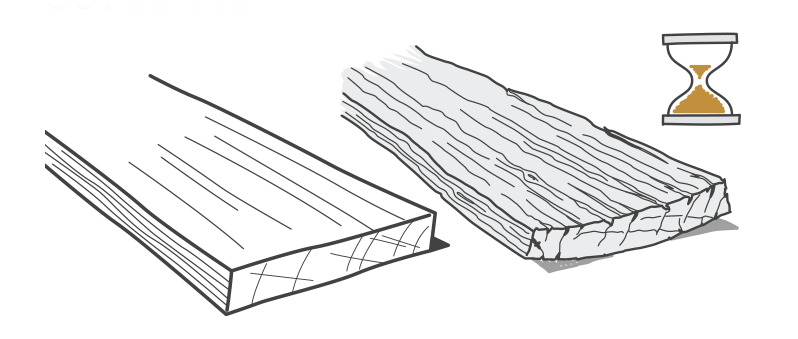

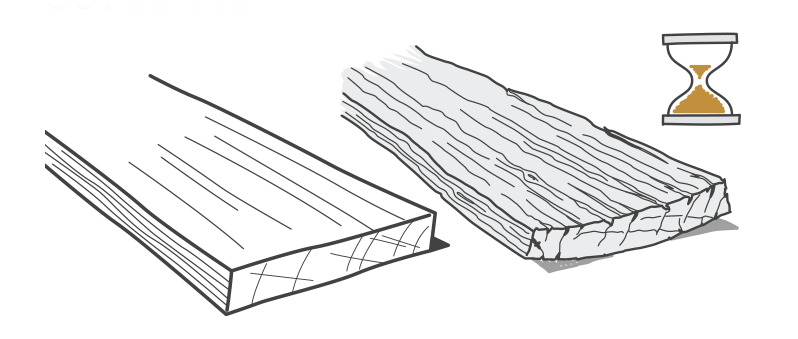

Water absorbed into wood makes it swell. Water movement out of wood makes it shrink. Wood exposed to weather cycles will keep swelling and shrinking until eventually your timber has warped, cupped and twisted out of shape. Once this happens, it is almost impossible to rectify. It is better to protect your timber properly from the beginning, so that your timber stays straight and usable for the longest period of time possible.

WHAT ELSE DOES CUTEK® DO DIFFERENTLY FROM OTHER OILS?

WHAT ELSE DOES CUTEK® DO DIFFERENTLY FROM OTHER OILS?

All CUTEK® oils help control water uptake and therefore timber movement. However, CUTEK® also has a unique product in Australia called CUTEK® Wood Preservative.

Not only does CUTEK® Wood Preservative keep your timber stable – CUTEK® Wood Preservative coated wood also resists damage caused by fungal decay, mould and termites. If you are serious about protecting your timber in the best way, for the longest service life possible, choosing CUTEK® Wood Preservative is the way to go – and bonus – you can add Colourtones to all CUTEK® oils if colour retention is also high on your priority list!

Please note – this advice only applies to pre-oiled timbers. If your wood has had another coating applied after installation, then you will need to do further assessments to determine how best to remove the coating/barrier BEFORE using CUTEK®. CUTEK® has other products available to help in this situation (e.g. CUTEK® Wood Stripper). If in doubt, please call one of our friendly CUTEK® timber experts who will be more than willing to help you troubleshoot your particular project.

The best thing to remember is this: CUTEK® needs to get into your wood, so that water can’t. If there is something stopping CUTEK® from penetrating fully, then you need to remove that barrier before your first application of CUTEK® oil.

But here is the best part: Once you have used CUTEK® for the first time, maintenance in the future is simple and easy! The next time you need to refresh your timber, just clean and reapply. No sanding, stripping or other frustrating procedures required!

WHAT ELSE DOES CUTEK® DO DIFFERENTLY FROM OTHER OILS?

WHAT ELSE DOES CUTEK® DO DIFFERENTLY FROM OTHER OILS?